We can not live without water which is must to our daily life. From taking showers to brushing our teeth, washing clothes and making drinks- most of the things we use water. That is the one way to get water. Has it ever crossed your mind where the water in that bottle comes from? How Water Bottles Are Made & The Process To Making Them**)&

Still water comes from a variety of sources like natural springs, wells, or the city. This water is then brought to somewhere called a bottling pant where they get ready the waters for our funnels. The water, which has been cleaned of dirt and other nasty things that may be found in the natural reserves it came from is then tumbled into plastic bottles. This is vital as we want the water to be drinkable by everyone.

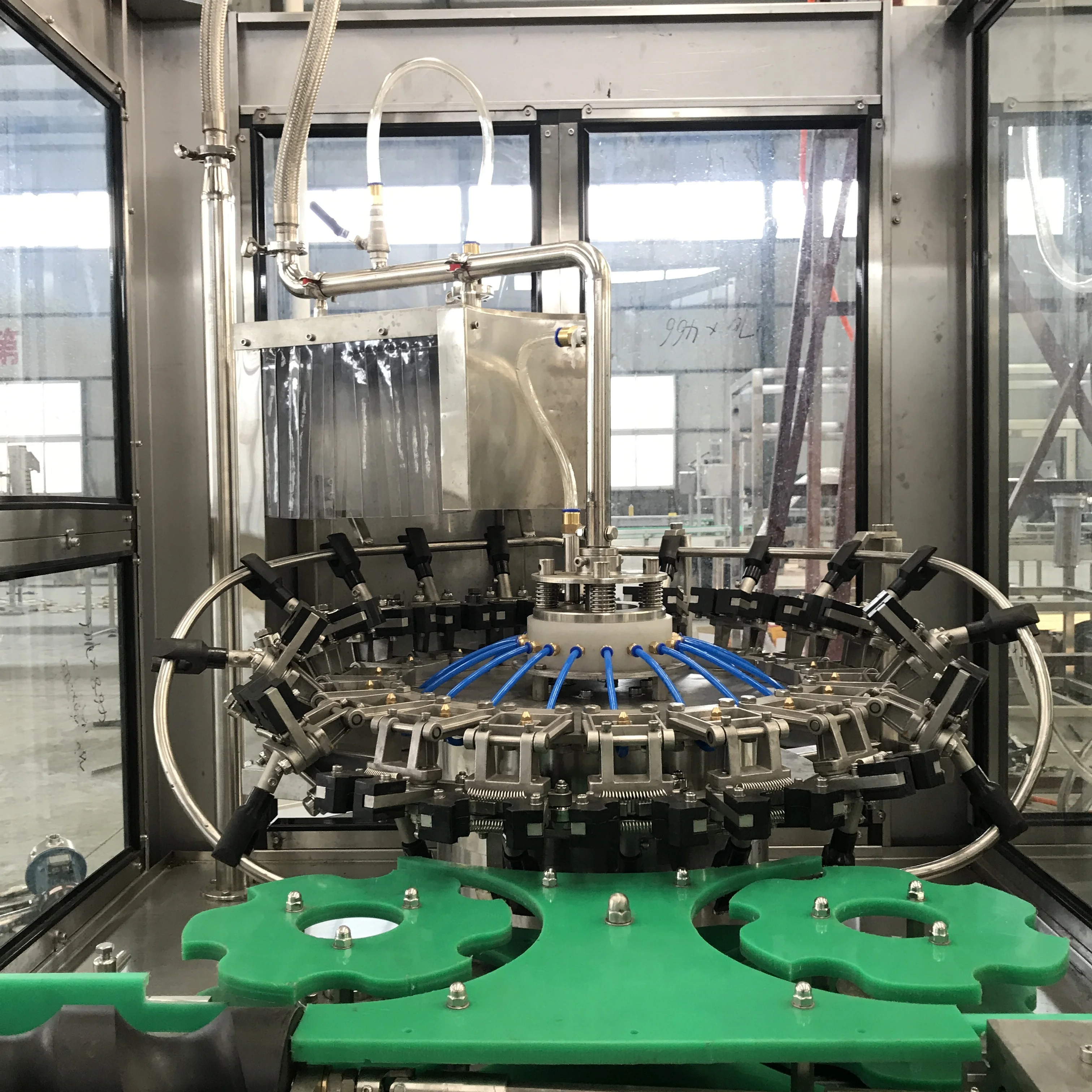

The process begins when bottles are fed onto a conveyor. The belt is there to do that lifting for the bottles being transported from one place to another. The bottles are washed with hot water and non-hazardous chemicals in order to be 100% clean and sanitized for drinking use. After being rinsed, the bottles move to another conveyor belt where water is added. A machine is employed to ensure equal levels of water in each bottle, so that no one out there gets an empty or extra soaked batch.

Once the bottles are filled they each have a cap put in place. It is performed by a machine that heat seals the cap tightly. The machine also applies a label to the bottle, which contains product identification information including date and lot number. At last, the bottles are placed into cartons and shipped to stores for purchase by our own selves.

Bottled water companies have a desire to be more environmentally friendly and contribute to saving the planet. They are constantly seeking ways to conserve energy and get more mileage out of their waste. They achieve so by employing lighter bottles that require less plastic. They can also help save waste from being dumped into landfills by using less plastic.

The government tests bottled water to see if it is safe. Attempting to ensure our drinking water is safe and healthy, the following are a few of the important guidelines bottled-water manufacturers have to follow. These regulations are in place to safeguard the consumer and gives them confidence that they will receive clean drinking water.

In the USA, bottled water is regulated by The Food and Drug Administration (FDA) that ensures they are safe. That is because FDA has rules about how much bad stuff can be in the water (which helps to keep our own drinking etc). The firms must also reveal where the water was taken from and describe measures used to clean it before bottling.

offer turnkey solutions meet the various needs customers. professional water bottling production linewill design layout based the requirements your.

make use durable materials for foundation of equipment as well as food grade stainless steel 304/316 filling nozzles. Besides the stainless steel, also cooperate famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. will test the machine before packing and give the water bottling production linethe manuals and spares.

As business with wealth knowledge packaging solutions, can give water bottling production linemost effective solution according customer's requirements budget. Budgets will determine various solutions. engineer will help customers cut costs and increase working efficiency.

are a professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. have 10 water bottling production lineskilled engineers in design development with over 15 years of experience in packaging field. are able customize our machines meet customer needs. offer a professional after-sales service that can assist customers with their issues quickly.