Did you ever wonder how your drink, the favorite one pours into a glass bottle? It’s really interesting! All of this is performed with the help of a glass bottling machine, which has the function to prepare bottles and fill them in. This incredible device is responsible for making everything from bottles of soda, juice and even beer that much quicker. It simplifies the whole process and makes it faster.

What is really amazing of the glass bottling machine, because put together all 3 key things in order. It starts off by filling the bottle with your favorite beverage. Then it puts a cover over the bottle to retain freshness and bubbles. That is crucial — it preserves the taste of the drink and bubbles! It also labels your bottle for easy identification. The label make tells you that soda, juice, or another type of beverage.

Because before glass bottling machines, people were filling each and every bottle by hand. It was time-consuming and prone to errors. There was a time when bottles would break sometimes or mess instead of filling the right quantity. However, many bottles can now be filled in a few minutes with the glass bottling machine and increased efficiency without errors. This is because the machine uses smart technology which plays a huge role in ensuring it works effectively. Well, not only does this expedite the process exponentially but it also creates a much more accurate outcome — win-win!

Well, booze bottles especially can be found in many shapes and sizes. For instance, a mini juice bottle would appear distinct from that of a giant bottle of soda. The positive side is that, the glass bottling machine can be used with various types of bottles. That makes it suitable for packaging everything from tiny energy drinks to large beer bottles. This adaptability is crucial that many outlets produce different beverages without the need to make use of individual machines for each.

If you are a drinks company on larger volumes of bottling such as factories or soft drink plants then the glass blowing machine is an excellent solution. It helps save money on workers because a machine can do the work of several people. It also speeds up the number of drinks you can make, crucial for those high-demand times. Given that equipment costs are a one-time fee when buying the device outright, this can be an economical option over time too. That way businesses can use that money on other areas of their business to help them grow and succeed.

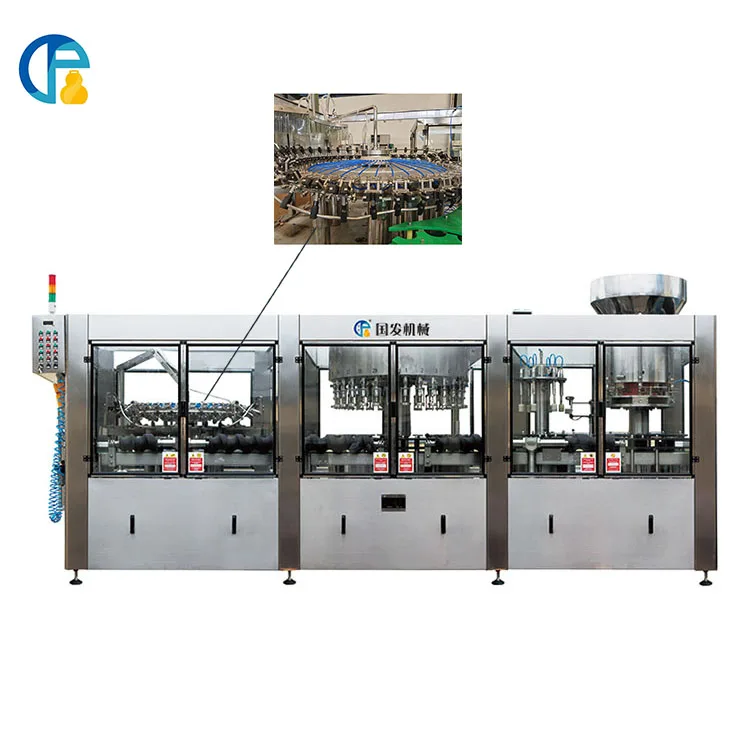

equipment's base constructed from sturdy materials the filling nozzles made food-grade stainless steel. Besides stainless steel, we also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Prior to shipping, will analyze the machine and provide manuals and spare parts for the glass bottling machine.

are professional liquid packaging solution expert for liquor,water,oil,detergent,liquid shampoo,etc. Ten glass bottling machineengineers in design development with over 15 years of experience in the packaging industry. can tailor the machines satisfy the specifications of customer. offer professional after-sales service that will assist customers solve their problems within a short time.

As professional business can offer turnkey solutions that meet customer's needs. customer needs inform us details of his requirements, including workshop layout, bottle cap photos,etc. experts will develop an arrangement based on the buyer's request.Feel free to reach out to our glass bottling machineteam if require an all-inclusive line solution for packaging liquids.

As company with years expertise packaging solutions, we'll offer customer most suitable glass bottling machinethat meets needs of customer and budget. Budgets can dictate best solutions. engineer will help customers reducing expenses increasing efficiency work.