Remember World's Most Amazing Videos, and the machines that packed glass bottles so perfectly good? Want to have the machine which is made especially for not having your products damaged.Isn't?>> This makes room for a filling machine glass bottles. This post will be looking at how these machines operate and why they are the best for businesses that deal in glass bottles.

Glass bottle are so fragile. Now the downside to these massive white boards are that they're kind of brittle and can wind up being worn out pretty easily right after the first few months. Glass bottle packing machine that has gotten very pervasive and useful also in the last decade or so with many businesses relying on this to ensure their product stays safe, lest those bottles are shattered into pieces while being transported by them. This one machine is very powerful and that it will keep the bottles safe in a manner such as to not break when you are transferring your stuff from one place to another. This machine is deployed words of certainty and security for businesses when it comes to their products.

This is because a glass bottle packing machine has arrived to provide an excellent solution for companies that want ro pack many quantities of bottles, or even will be able to do the job faster and more efficiently. It can handle bottles of variety size and shape, so convenient for wide range products. The flexibility is important too, since different products are packaged in a variety of glass bottles. The device is very easy to use so when employees will start using the equipment they can easily get used with it again. This device will reduce the time and work that people were wasting in packing bottles manually, most businesses can make use of this machine. Most of all: This machine is designed to pack bottles in the most perfect container that will enable them to be shipped safely at their destination.

By using a glass bottle air tin can filling machine, this development makes it possible to optimize the production process in companies. This machine can rapidly, but effectively fill the containers into required packaging. But to sum it all up, these techniques make the process of packing and shipping out your business's wares much quicker than if you did everything manually. Additionally, this machine can minimize the Manforce in a great amount. By alleviating this manual labor, companies can be more efficient throughout. Companies that need to pack a ton of bottles in just 2 hours should definitely use this machine, as it will be useful for them if they want their customers happy with the products being made faster!

This glass bottle packing machine saves time for businesses and they do not have to make up so much effort. It is time consuming and physically demanding to package bottles manually. This can further complicate the task and increases opportunities for error. With the help of this machine businesses can easily and quickly pack their bottles. Not only does this speed up the process, but reduces errors that could lead to products being spoiled. This industrial machine helps workers focus on other tasks essential for a good operation.

offer turnkey solutions meet the various needs customers. professional glass bottle packing machinewill design layout based the requirements your.

are professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. 10 experienced design development engineers with over 15 years of experience in packaging field. are able customize our machines to meet your needs. We provide a professional after-sales glass bottle packing machinehelp our customers resolve issues swiftly.

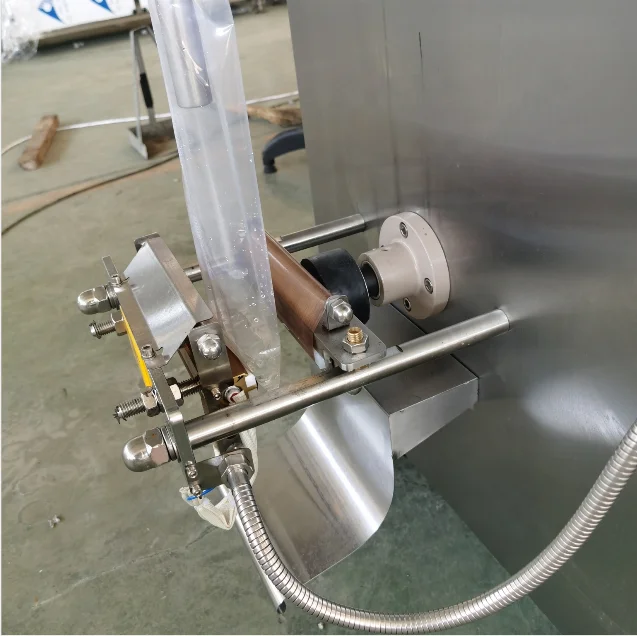

base of equipment made of sturdy materials, the filling nozzles are made with stainless steel that is food glass bottle packing machine. Besides stainless steel, also cooperate with famous brand Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Before packing,we will debug machine and supply manuals and spare parts for the buyer.

As business with wealth knowledge packaging solutions, can give glass bottle packing machinemost effective solution according customer's requirements budget. Budgets will determine various solutions. engineer will help customers cut costs and increase working efficiency.