A gear pump filling machine is a specialized piece of machinery that aids in the transfer of liquid products into vessels such as bottles or jars. It all happens very fast, and closely. This machine has a pair of working gears that when turned, assist in combining the liquid inside to be placed directly into containers. So, it can fill a lot of containers within no time and is indeed beneficial for factories generating many products.

The use of a gear pump filling machine in the factory will save time and effort. This machine is a quick way to fill many containers quickly, rather than just filling the bottles by hand or using some slow process. It is especially critical for a business, which needs to manufacture large number of products at speed necessary in order to keep up with the demand on customer side.

It is also very efficient in terms of material utilization that means it will save the liquid from being wasted and this makes gear pump filling machine a top choice. Not only is this good for the environment, but it saves you money as well. Even if you accidentally put too much liquid into one of those containers, the machine still has equal amounts going to each container so don't need to worry about spillage. This keeps the quality of products high.

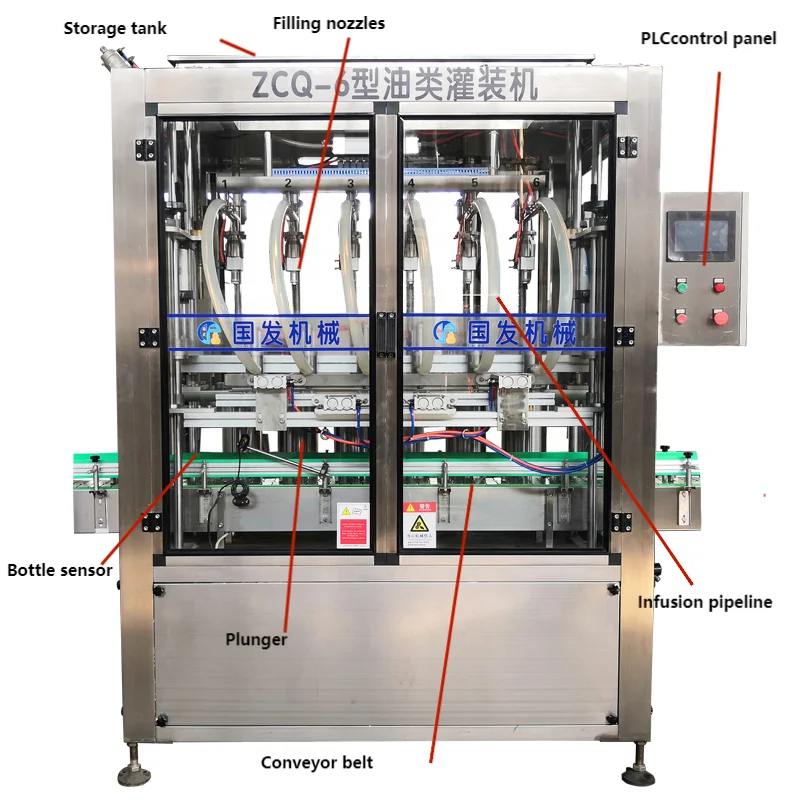

The technology of the gear pump is important in enabling containers to be conveniently filled with exemplary accuracy. Crucially, the gears in this machine are all turning and engaging to get that liquid into those containers perfectly. The gears are uniquely designed so that each tank is conveyed the same volume of liquid, which is imperative when ensuring uniformity between single product or items. This ensures the quality of nasal spray products is both consistent and reliable.

If you wish to fill the containers in relatively less amount of time, a gear pump filling machine is what should be on your bucket list. This mean machine has the capacity to fill up hundreds of containers in a second! All these containers over a very short period of time, is nothing else but an excellent way for the business to save money, or even help with general operations (time).

Moreover, it is also easy to use the gear pump filling machine. Since you do not need to hire more workers to run it, the team can remain small and efficient. As one of the most popular types used in packaging lines, gear pump filling machines can fill pumps at high speed without sacrificing weight accuracy as they do so. First off you achieve your production rate without sacrificing quality.

Another time where the cram fill comes into play, which is when you are packing products such as liquid soap, detergent or sauces — containing roughly equal volumes of liquid in each bottle. Here a gear pump filling machine is used. The rig is made to fill every container the exact same amount which is very important to maintaining your products quality and consistency.

can offer turnkey solutions satisfy diverse customer gear pump filling machine. experienced team will develop layout that based on requirements.

are professional liquid gear pump filling machinesolution expert for liquor,water,oil,detergent,liquid shampoo,etc. 10 experienced engineering engineers who have over 15 years of experience the packaging industry. are able to customize the machines to suit customers' requirements. With professional after sales service, we can help customers solve problems promptly.

make use durable materials for the foundation the gear pump filling machineas well as food grade stainless steel 304/316 for filling nozzles. Besides the stainless steel, also cooperate famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. Prior to shipping, will analyze the machine, then provide manuals and spare parts for the buyer.

We'll offer most effective packaging solution customer according their budget and preferences. gear pump filling machinewill dictate different options. engineer will aid customer in reducing costs increasing efficiency the work.