Have you ever wondered how your favorite juice or shampoo gets inside those bottles before purchasing them from the store? The process is actually super fascinating!!! An automatic liquid filling machine is one of the most important types of machinery that companies employ for these tasks. Who are we Without this machine to keep, our favorite drinks and products packed nicely. But I leave the finer details to what is this machine and how do you make some of these businesses that produce such products better etc.

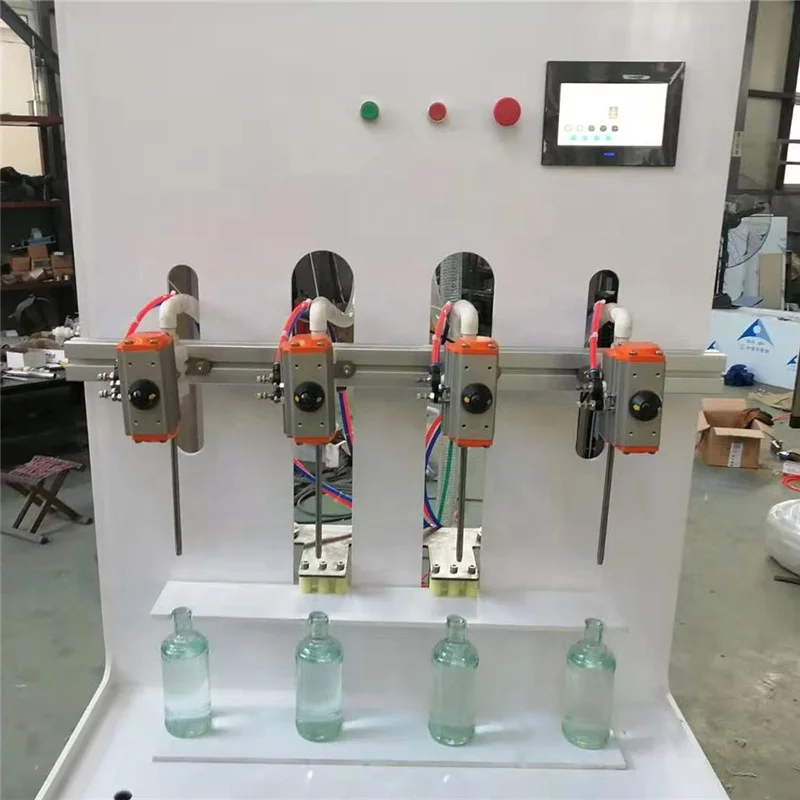

A fully automatic liquid filling machine is, as the name implies, a huge machinery that fills up bottles with all types of liquids at high speed. Such as soap, soda and cooking oil. Even better, it can do that all by itself without any assistance from humans! This is a significant advantage for businesses due to the fact that this device allows them to fast-track their projects. This can be a massive time-saver, and ensures all your bottles are filled to top-quality standards. Yes, this is critical as it ensures that the customer understands where they are in a stage and in what should be purchased or not.

So, what is fully automatic liquid filling machine and how it works actually? So if this is set up on one, it does the exact same thing each time across all other sites that are running. In this way, the machine turns on and pours a fixed volume of liquid in each bottle. That a bottle of anything on the shelf has another drop in it, lock stock and barrel. Yes, they are commission-only but hey — customers always get what they buy by the bottle. This keeps everyone happy!

Another great thing about the complete automatic liquid filling machine is that it refills bottles with most speed benefit. It is made in such a rapid manner which enables businesses to blast out more bottles rapidly This level of speed, in turn allows to produce more products and make a greater profit. If businesses can sell more things in an equal amount of time, then they like to fulfil the customer´s wish.

For their need, It is available in the wide range of them so they prefer to go with according to it then it will be more comfortable for people. For illustration, some machines have trouble processing thick substances like honey/syrup and other devices can process very viscous liquids. Hot Fill (~ 190 Degrees F)-Great for soup and broth if you want to bottle it after the batch has been freshly cooked! This type of flexibility allows for business to select the right machine based on their own item and needs.

For anyone selling their own product, investing in an automatic liquid filling machine could end up being one of the best things you ever did. It will just eliminate the time-consuming production. This possibility of becoming more accurate and working faster helps manufacturing companies to build much larger volumes. It not only help the organization to increase its effectiveness but also makes a way for customer satisfaction as customers are happy with getting performance-wise good products.

are professional liquid packaging solution expert liquor,water,oil,detergent,liquid shampoo,etc. Ten highly skilled engineers have more than 15 years experience in packaging field. We can customize machines satisfy customer's requirements. offer professional after-sales service help our customers resolve issues fully automatic liquid filling machine.

As business with wealth knowledge packaging solutions, can give fully automatic liquid filling machinemost effective solution according customer's requirements budget. Budgets will determine various solutions. engineer will help customers cut costs and increase working efficiency.

foundation of equipment made of sturdy materials. filling nozzles made of stainless steel that food grade. Besides stainless steel, we also cooperate with famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. will test the fully automatic liquid filling machineprior to packing and provide the purchaser the instructions and spare parts.

offer turnkey solutions meet the various needs customers. experienced team will develop layout fully automatic liquid filling machinewith your requirements.