Moving belt to which bottles are placed on the front end, first of all These bottles are moved around using a conveyor system to different stages of the bottling process. The bottles then proceed to the cleaning stage. This step is where an extravagant machine sprays water to get the inside of your bottle clean and shiny. This process helps free it from any sort of dirt dust or anything that you wouldnt like on your strands. Once the cleaning is done, machine pushes air inside bottle for complete dry of water.

This makes machines even more beneficial as they improve consistency. The two are made to make sure that there is an equal proportion of liquid in every bottle and ensure the bottling process. This ensures that each bottle will taste just like the previous one, which is important in maintaining a drink's quality for years to come. This is all about making sure each and every drink bought tastes as amazing time after time.

Beverage bottling machines and automation Automation is utilizing devices to play out an undertaking that typically requires human work. For beverages bottling, automation controls all these steps of bottling process. They are automatic machines that work for cleaning, filling, capping and labeling. In other words, they relieve human workers of the tiring and time-consuming manual work.

Automation is much to be desired. First and foremost, it speeds up the entire bottling process in efforts to keep up with drink demands. The other is a decrease in the percentage of errors that can occur during this procedure. Machines are incredibly precise, providing an extra layer of security over making certain that everything is done correctly. Finally, automation increases the safety and health by reducing work that may be hazardous to workers in terms of vision because it avoids heavy lifting tasks as are glass bottles or introduces hot liquid.

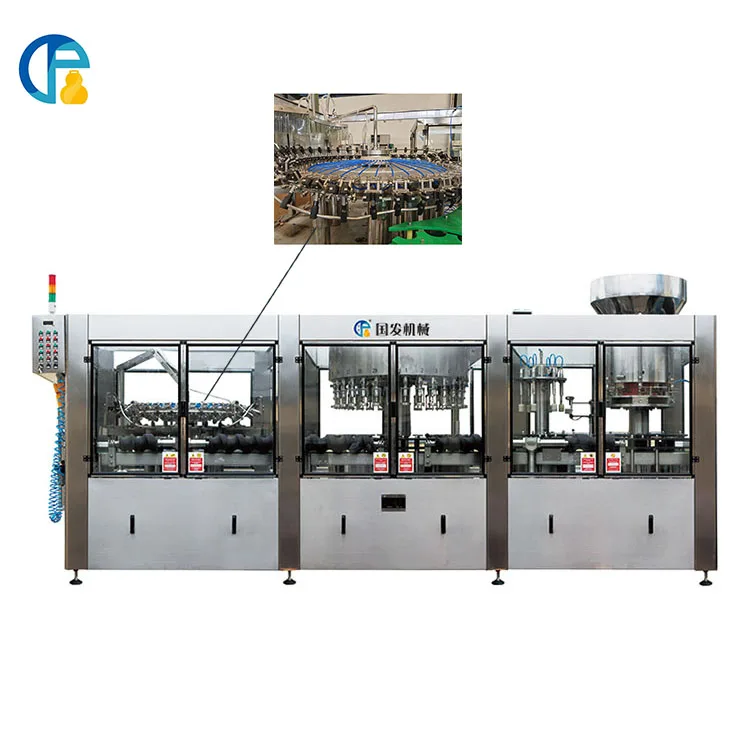

In the market, there are various types of beverage bottling machines on sale The rotary fillers are one type of these comprised fillings. A large wheel on this machine is equipped with a number of nozzles that fill the bottles as they pass underneath. This site is the gravity filler fillers, which work by filling up bottles usin gravitational strain to move water. Another type is called a volumetric filler, which measures the precise liquid necessary for each bottle and then pours it without human interaction.

The beauty of it is that beverage bottling machines are getting even more intelligent, and able to do this faster with the help of advancements in technology. One of them is detection sensors that utilize cameras to observe the bottling execution. Removal checks these bottles for any issues such as cracks or leaks. If a set point is exceeded, the packaging machine can halt or adjust bottle filling so that perfection prevails. This way where eventually reach the customers with high-quality bottles only.

Robots and artificial intelligence (AI) taking over control of parts in the bottling lines is another innovative development. Robots can take care of things such as moving bottles or lids, leaving human workers to address tasks that require more thinking and problem-solving. Artificial intelligence can analyze the data that is accumulated by those sensors and cameras to extract any trends or patterns, which serves to make bottling process as a whole more efficient.

can offer turnkey solutions meet the diverse needs of customers. buyer needs to tell us what they want, his workshop layout, bottle cap photos,etc.Our expert team will create an layout based on the customer's request.Feel at ease get in touch with sales team if require a turnkey line beverage bottling machinepackaging of liquids.

make use durable materials for foundation of equipment as well as food grade stainless steel 304/316 filling nozzles. Besides the stainless steel, also cooperate famous brand like Siemens,Schneider,Omron,Autonics,Mitsubishi,etc. will test the machine before packing and give the beverage bottling machinethe manuals and spares.

are professional liquid packaging solution expert for liquor,water,oil,detergent,liquid beverage bottling machine,etc. 10 experienced designers and developers with over 15 years of experience in packaging field. We able to customize the machines according to the specifications the customer. provide professional after-sales services help our customers resolve issues quickly.

We firm with extensive expertise packaging solutions, we'll provide customer best solution according customer's requirements budget. Budgets can dictate best beverage bottling machine. engineer will help customer save money while increasing working efficiency.